Facilities

Standardized Process Control

Celltrion Pharm develops reliable products through

GMP-certified systems and strict quality control

Cheongju Plant

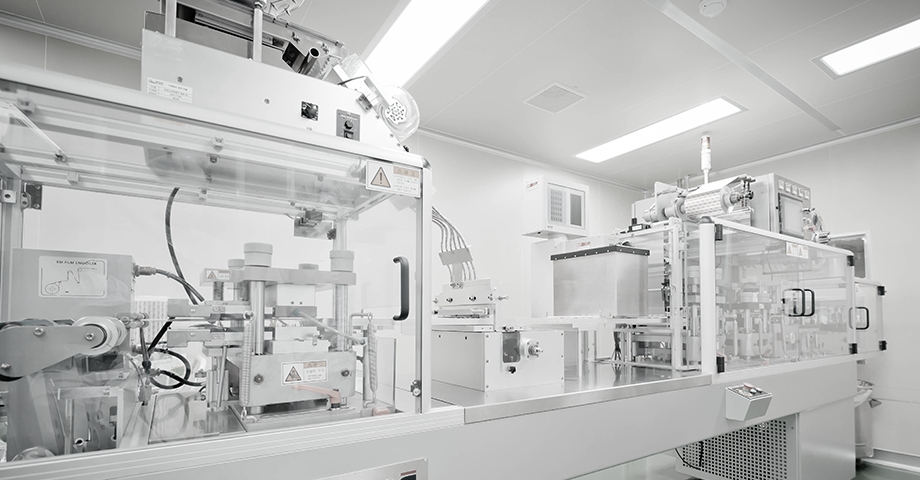

Celltrion Pharm’s Cheongju Plant in Ochang, Chungcheongbuk-do is the Celltrion Group’s development and production base for chemical pharmaceuticals. It is the first Korean production facility to obtain GMP certifications from the United States and the European Union for oral solid manufacturing .

Cheongju Plant has the infrastructure that is capable of supplying tablets and capsule formulations to any market in the world. Its supply chain management system encompasses the overall packaging and logistics chains.

(production capacity: 5 billion tablets as of 2020)

| Process | Major equipment |

|---|---|

| Granulation |

Wet: Huttlin (1,315 L) and 3 others Dry: Gerteis (300 kg/h) |

| Blending |

Bin Mixer: Muller (200–1200 L/kg) and 2 others |

| Tablet Press |

Fette (single tablet, 296,700 T/h) and 3 others Kilian (double tablet, 275,000 T/h) and 1 other |

| Capsuling |

IMA (100,000 cap/h) |

| Coating |

IMA (650L) and 3 others |

| Inspection |

Viswill (200,000 T/h) and 3 others, NFA (250,000 T/h) and 1 other |

| Packaging |

CVC (250 bottles/m) and 6 others Hoonga (400 cartons/m) and 2 others |

| Automatic Management System (AMS) |

Building Management System (BMS) Warehousing Management System (WMS) Raw Material Weighing System (RWS) |

Celltrion Pharm Cheongju Plant has its production lines for prefilled syringes and auto-injectors. It plans to expand its pharmaceutical portfolio to include injectables.

Jincheon Plant

Located in Jincheon, Chungchengbuk-do, the Jincheon Plant produces key chemical pharmaceuticals for domestic distribution. The plant obtained a Korea Good Manufacturing Practice (KGMP) certification. It holds facilities and equipment capable of manufacturing around 800 million high-quality tablets and capsules per year.