Celltrion Pharmaceutical's emission pollutant management performance

Celltrion Pharmaceutical not only strictly adheres to legal emission limits to minimize the environmental impact from air and water pollutants but also establishes its own enhanced standards to manage these issues more rigorously. Through this approach, the company aims to prevent air and water pollution and contribute to sustainable environmental protection.

| |

Category |

Unit |

Emission Allowance Standards |

2022 |

2023 |

2024 |

| Water pollutants |

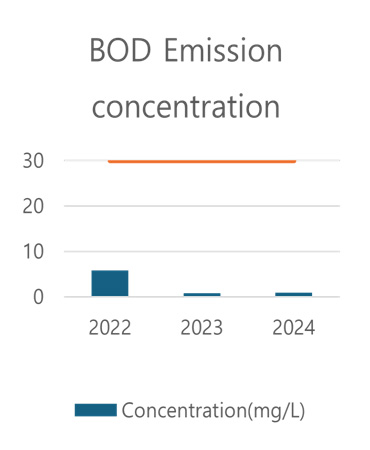

BOD Emission concentration |

mg/L |

30 |

5.8 |

0.8 |

0.9 |

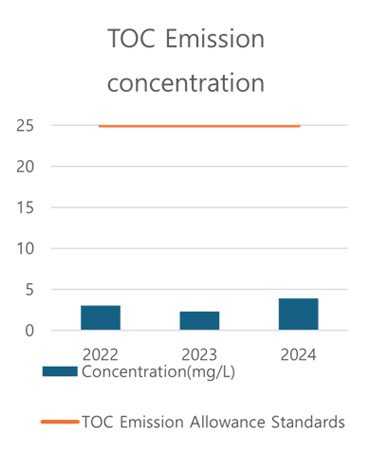

| TOC Emission concentration |

mg/L |

25 |

3.0 |

2.3 |

3.9 |

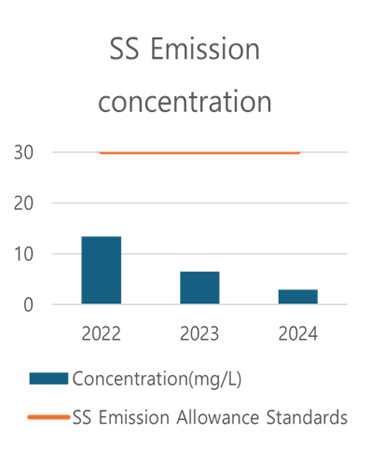

| SS Emission concentration |

mg/L |

30 |

13.4 |

6.5 |

3.0 |

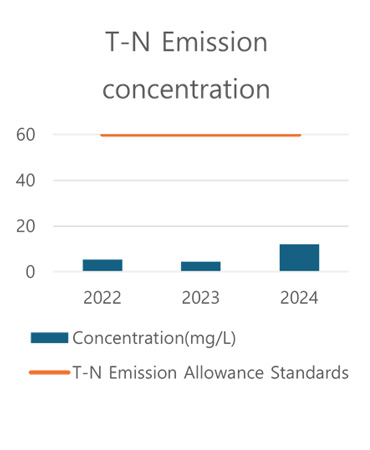

| T-N Emission concentration |

mg/L |

60 |

5.3 |

4.4 |

12.1 |

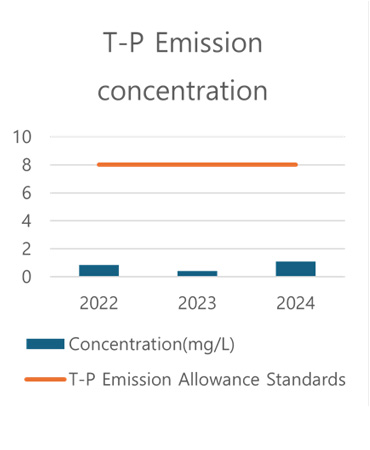

| T-P Emission concentration |

mg/L |

8 |

0.9 |

0.4 |

1.1 |

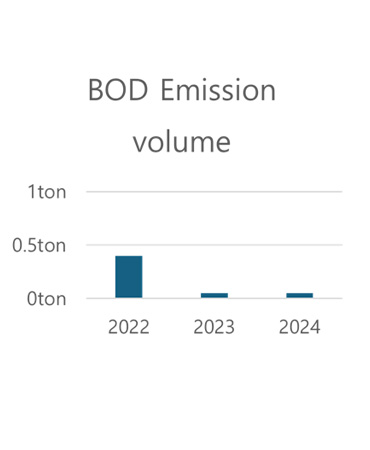

| BOD Emission |

ton |

- |

0.40 |

0.05 |

0.05 |

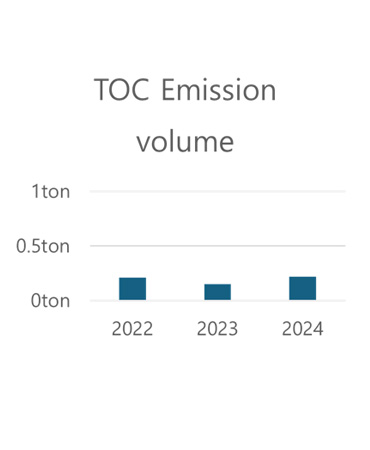

| TOC Emission |

ton |

- |

0.21 |

0.15 |

0.22 |

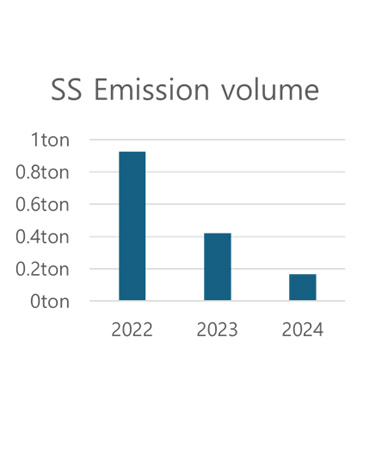

| SS Emission |

ton |

- |

0.93 |

0.42 |

0.17 |

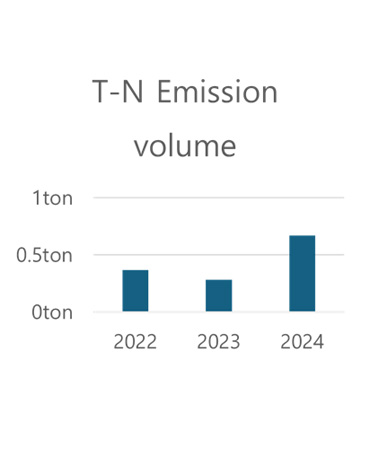

| T-N Emission |

ton |

- |

0.37 |

0.28 |

0.67 |

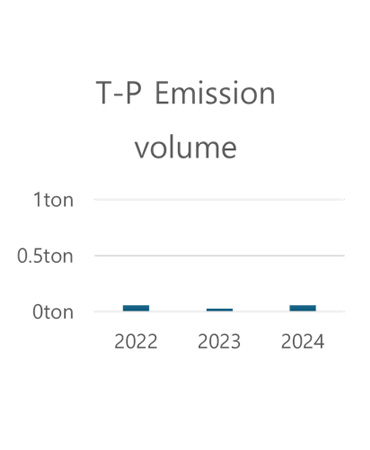

| T-P Emission |

ton |

- |

0.06 |

0.03 |

0.06 |

| Air pollutants |

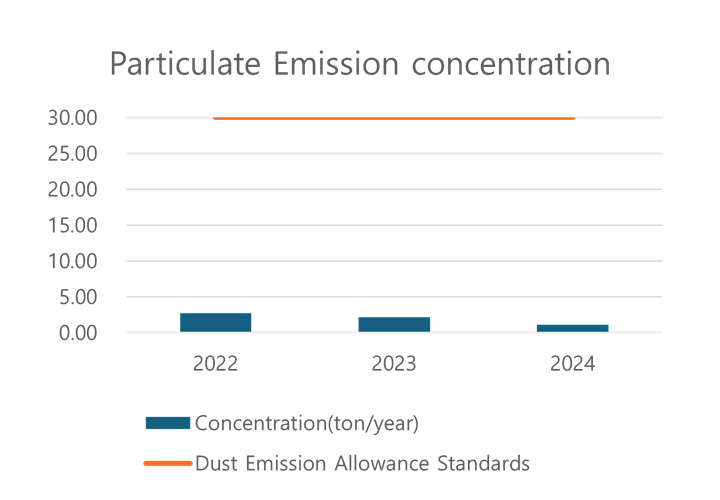

Particulate Emission concentration |

mg/S㎥ |

30 |

2.70 |

2.20 |

1.10 |

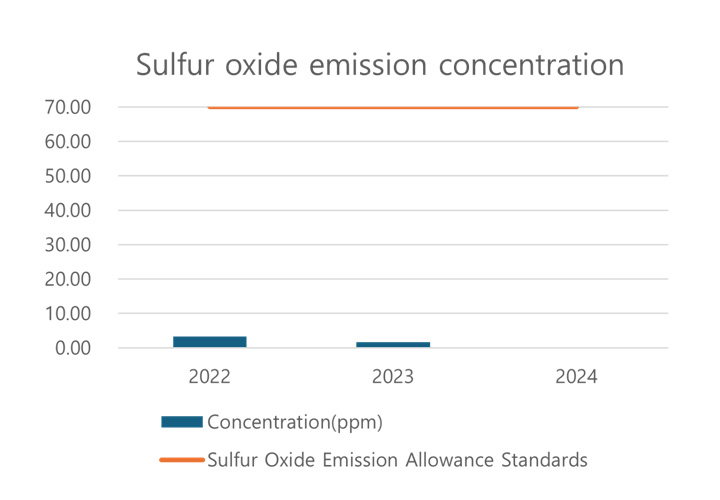

| Sulfur oxide Emission concentration |

ppm |

70 |

3.30 |

1.60 |

0.00 |

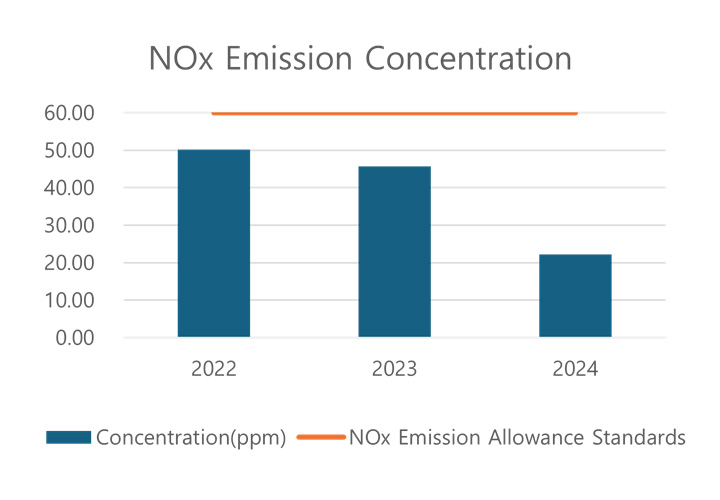

| NOx Emission concentration |

ppm |

60 |

50.15 |

45.75 |

22.15 |

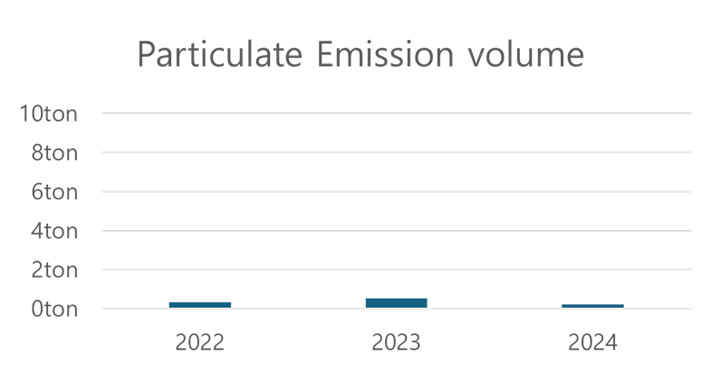

| Particulate Emission volume |

ton |

- |

0.33 |

0.53 |

0.20 |

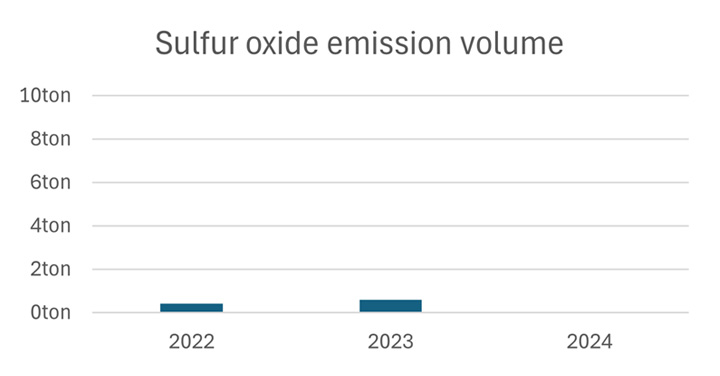

| Sulfur oxide emission volume |

ton |

- |

0.40 |

0.60 |

0.00 |

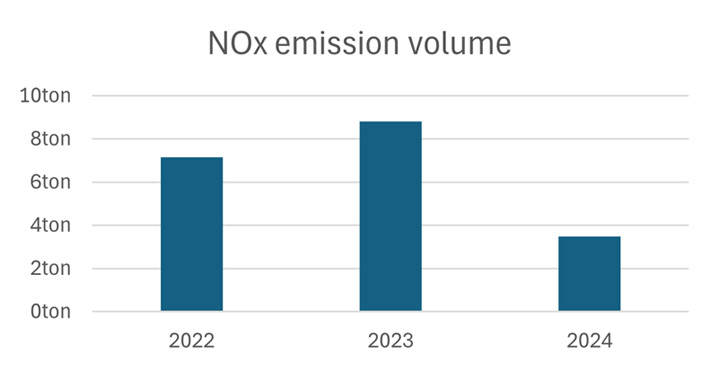

| NOx emission volume |

ton |

- |

7.15 |

8.81 |

3.48 |

1. Air pollutants management

Celltrion Pharmaceutical regularly monitors air pollutants through biannual and monthly self-measurements and conducts daily inspections to ensure the proper operation of prevention facilities. Additionally, the company applies its own enhanced standards, which go beyond legal requirements, to strictly manage pollutants.

2. Water pollutants management

Celltrion Pharmaceutical conducts thorough water quality management through wastewater treatment monitoring, biannual self-measurements, and its own enhanced emission limit standards. Wastewater generated from production processes and utility facilities is treated at the in-plant wastewater treatment facility before being discharged to the industrial complex's public wastewater treatment facility, thereby minimizing water pollution.

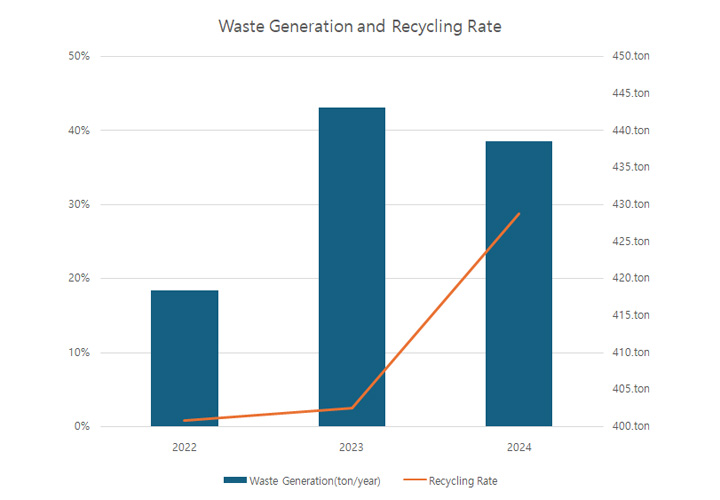

1. Strengthening waste recycling

Celltrion Pharm has consistently improved its recycling rate from 2022 to the present. All sludge generated from the wastewater treatment process is fully recycled and used for fuel production, while recyclable waste organic solvents are also being recycled. Furthermore, the company plans to expand recycling efforts for currently non-recyclable waste in the future.

Waste Generation and Recycling Rate

|

Unit |

2022 |

2023 |

2024 |

| Target Waste Generation |

ton |

450 |

475 |

500 |

| Waste Generation |

ton |

418.38 |

443.16 |

463.61 |

| Waste Recycling Volume |

ton |

3.72 |

11.35 |

145.12 |

| Recycling Rate |

% |

0.9 |

2.6 |

31.3 |

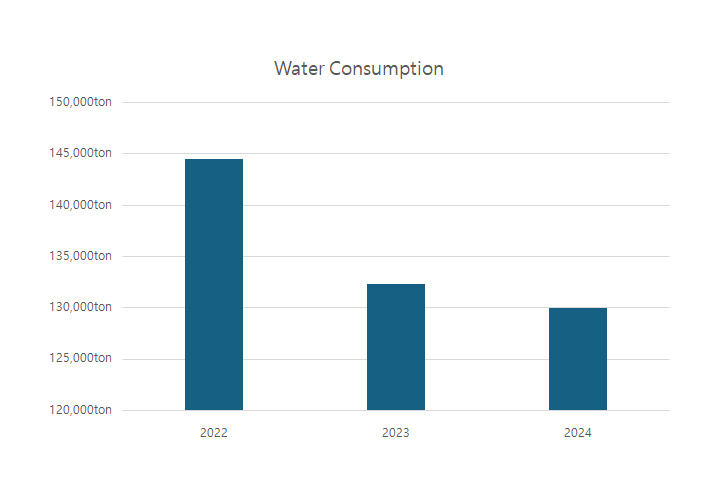

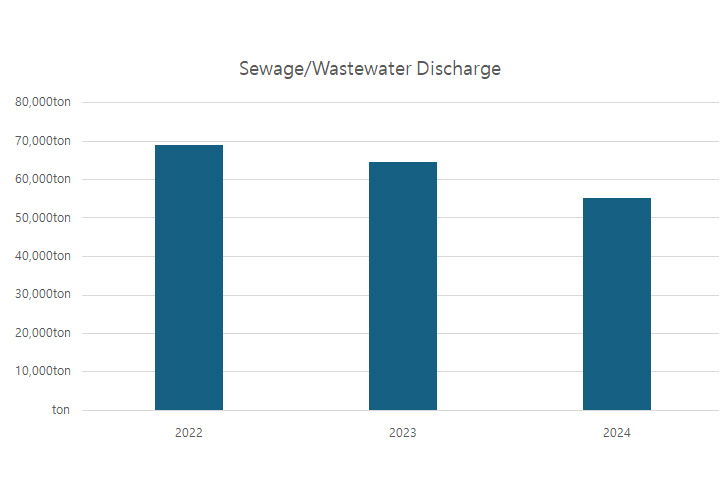

2. Water Resource Recycling and Minimization of Wastewater Discharge

Celltrion Pharm is striving to minimize water usage in its manufacturing processes and increase the rate of water reuse. The company has implemented water reuse facilities that recycle RO reject water generated during the pure water production process, reducing annual water consumption. Additionally, it continues to decrease the discharge of wastewater and sewage.

Water Usage and Wastewater/Sewage Discharge Volume

|

단위 |

2022 |

2023 |

2024 |

| Water Consumption Target |

ton |

170,000 |

150,000 |

140,000 |

| Water Consumption |

ton |

144,543 |

132,337 |

129,965 |

| Industrial Water Usage |

ton |

40,330 |

39,049 |

39,205 |

| Domestic Water Usage |

ton |

104,213 |

93,288 |

90,760 |

Sewage/Wastewater

Discharge |

ton |

69,177 |

64,703 |

55,333 |

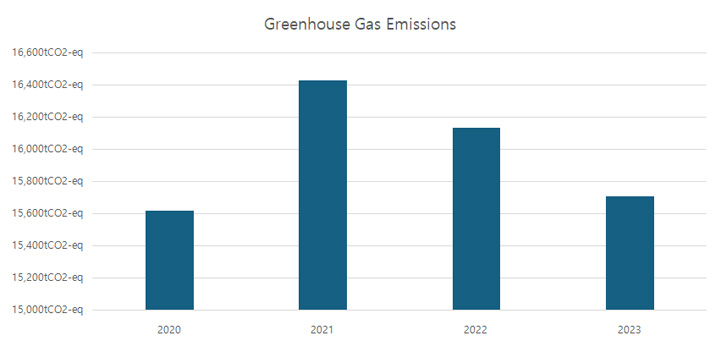

Celltrion Pharm is making various efforts to continuously reduce greenhouse gas emissions. To lower direct emissions (Scope 1), the company is implementing practical reduction measures such as transitioning internal combustion engine vehicles used for business purposes to eco-friendly vehicles and replacing boilers with ultra-low NOx burners. Additionally, to reduce indirect emissions (Scope 2), it has improved energy efficiency by introducing inverters in air conditioning systems, thereby further mitigating greenhouse gas emissions effectively. Moving forward, Celltrion Pharm plans to adopt solar power systems and install energy-efficient equipment, aiming for sustained emission reductions.

| Category |

Unit |

2021 |

2022 |

2023 |

2024 |

| Greenhouse Gas Emissions |

tCO2-eq |

16,430 |

16,135 |

15,706 |

15,490 |

| Facility Investment Status |

- |

- |

Installation of

Ultra-Low NOx Burner |

Adoption of

Air Handling Unit Inverter |

Installation of additional Ultra-Low NOx Burner,

Adoption of additional Air Handling Unit Inverter |

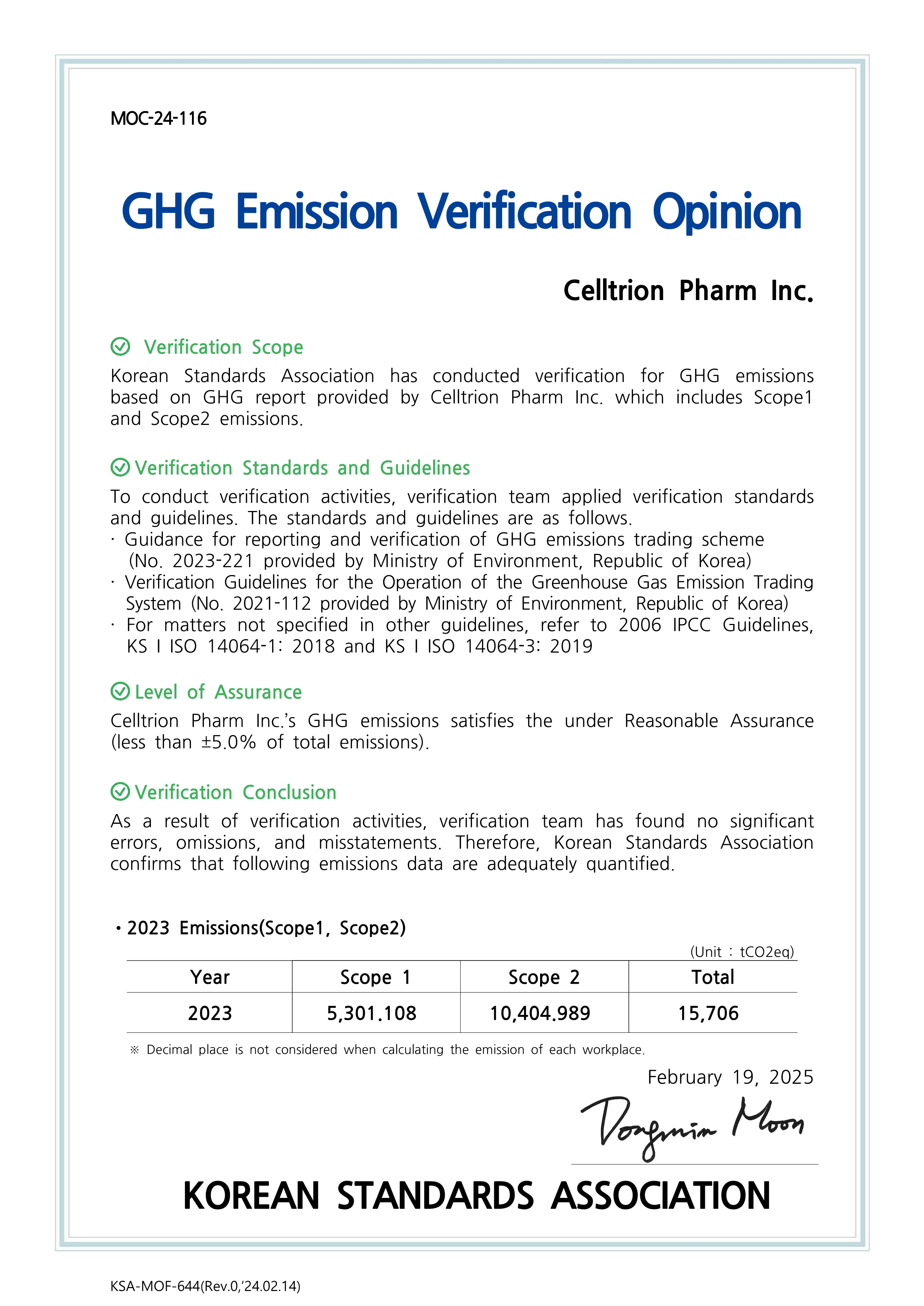

Greenhouse Gas Emissions Verification Opinion Statement

Celltrion Pharm actively operates various energy management programs to reduce energy consumption and improve efficiency, including the introduction of new equipment and optimization of equipment operation methods. Every year, we adopt additional ultra-low NOx burners and air conditioning inverters to reduce greenhouse gas emissions. We plan to further expand efforts to enhance energy efficiency at our facilities, including the implementation of eco-friendly energy systems.

Energy Consumption

|

Unit |

2022 |

2023 |

2024 |

| Energy Consumption |

TJ |

329.905 |

321.443 |

317.183 |

| Fuel Energy Consumption |

TJ |

110.156 |

104.017 |

101.286 |

| Electricity Consumption |

TJ |

219.749 |

217.426 |

215.897 |

| Energy Intensity |

TJ/100million KRW |

0.085 |

0.082 |

0.066 |